News

Salt Spray Testing in the Industry

The gradual degradation of metals by a chemical reaction is called Corrosion. In other words, a corrosive reaction would occur when a metal is exposed to an oxidant (oxygen) creating an electrochemical oxidation. Rusting of iron is one of the most common examples of corrosion that the general population is aware of. Since corrosion is common and can happen to most metals used commercially, theories and ways to protect metals from corrosion were developed. Applied coatings (paints, etc.) and reactive coatings (zinc, etc.) are some of the typical coatings used for the protection of metals from corrosion. Once the methods of protection from corrosion were developed, there was a need to test these processes to scale them on the benchmarks of time, cost effectiveness and overall performance.

Salt spray testing was identified and accepted as the standardized corrosion test methodology. The salt spray test helps determine the resistance of the metal and coatings against corrosion. With this test, a corrosive medium is produced to evaluate the coating used as the defensive finish for the metal. The salt spray test is cost effective, standardised and repeatable which makes it extremely popular in industry. It works on the principle of creating a corrosive environment and then observing and recording the time taken for corrosion products to appear on the test samples. Additionally, the comparison of actual test results v/s expected corrosion resistance of metals can be made. Thus, the salt spray test is quite often used for quality audit purposes in production processes for firms which deal in metallic products.

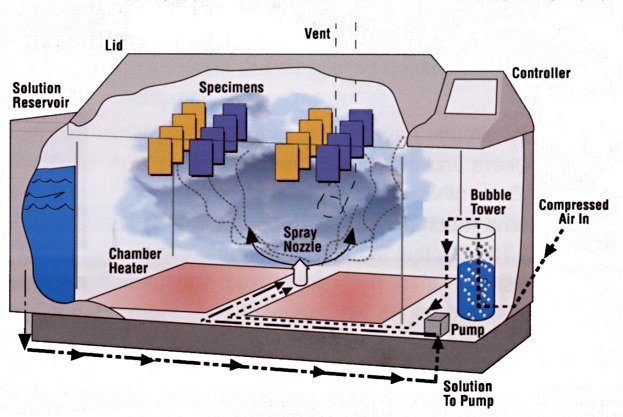

The salt spray test is performed using a test chamber that is closed, where a pure solution of salt water is atomised using spray nozzles. The salt water solution is typically comprised of five percent sodium Chloride (NaCl) mixed in deionized water. These tests are commonly performed in accordance with the national and international standards of ATSM B 117 and ISO 9227. These standards identify important parameters with which the tests should be conducted. Parameters such as salt solution pH, specific gravity, temperature, air pressure etc. are specified and recorded during the test. This requires continuous (usually daily) checks of the test parameters to ensure compliance with the standards. Also, the performance of one coating might differ with another during salt spray exposure, thus requiring different durations while testing different metals and coating combinations.

https://www.gcclp.org/profile/stockholm-diamond-league-2022-live-tv-coverage-online-on-30-june-2022/profile

https://www.gcclp.org/profile/stockholm-diamond-league-live-coverage-onlin-hd-30-june-2022/profile

https://www.gcclp.org/profile/stockholm-diamond-league-live-coverage-free-on-tv-30-june-2022/profile

https://www.cityballetsf.org/profile/stockholm-diamond-league-live-coverage-online-hd-tv-30-june-2022/profile

https://www.celebritytheatre.com/profile/stockholm-diamond-league-2022-live-op-tv-livestream-gratis-30-juni-2022/profile

https://www.celebritytheatre.com/profile/stockholm-diamond-league-live-coverage-online-on-30-june-2022/profile

https://www.celebritytheatre.com/profile/stockholm-diamond-league-2022-live-coverage-broadcast-on-hd-30-june-2022/profile

https://challonge.com/3avomjaj

https://pastebin.com/sgRq0KLD

http://cpp.sh/4ahrn

https://pastebin.com/QfKkjztF

http://cpp.sh/6rly4

https://pastebin.com/6rzaWQ9V

http://cpp.sh/4wiyz

https://pastebin.com/Nn4Ueg4X

http://cpp.sh/8nhia

https://pastebin.com/RAyy36aQ

http://cpp.sh/5xkx2b

https://pastebin.com/ivhy8t3V

https://www.geany.org/p/rs57P/

https://pasteio.com/x9C7kOOABWrX

https://pasteio.com/xR73FWSGPYic

https://paste.tbee-clan.de/#

https://pasteio.com/xt0TKN6i3pP7

https://www.geany.org/p/DqTnU/

https://paiza.io/projects/cvM72WHOWCmlZM-jGLosFg?language=php

https://jsitor.com/5aii6lRuq

https://dotnetfiddle.net/EItTGC

https://ide.geeksforgeeks.org/d9ebaf25-3124-40b3-b984-168c161f74fc

https://dotnetfiddle.net/unchbP

https://rextester.com/ORXC7993

http://cpp.sh/7ncts4

https://jsitor.com/Q0UpxuWuM

https://ide.geeksforgeeks.org/5c8ec5a4-7000-498b-aef4-123874b0b52e

https://ideone.com/S3Yyy1

https://jsfiddle.net/anikpaul/pa62b03y/1/

https://www.geany.org/p/LSSvV/

https://dotnetfiddle.net/DdxMsw

https://dotnetfiddle.net/47LzdB

https://yamcode.com/t1ijsrd5j1

https://note.vg/fdg-ufy-ysyy

https://bitbin.it/04U30TD6/

https://codebeautify.org/alleditor

https://paste2.org/5JKxawpP

http://paste.jp/93d9e1c6/

https://paste.ee/p/LkE0i

https://pastehere.xyz/gstA6bbC5/

http://cpp.sh/9ve63

https://rentry.co/dio77

https://txt.fyi/-/22180/a694f451/

https://notes.io/qyqGq

https://challonge.com/5fhx8kfh

https://ctftime.org/team/193486

http://cpp.sh/7nuwzl

http://cpp.sh/7lx7d

https://paiza.io/projects/D73fA1MpF6ky2cdvjlUL0g?language=php

https://challonge.com/4h2ya0uh

https://ideone.com/YKNIrq

https://tech.io/snippet

https://pasteio.com/xLyC1aUFkfPO

https://dotnetfiddle.net/qj7C3Z

https://ide.geeksforgeeks.org/b5ec4bff-a236-4184-b63d-76ece1a2a6ba

https://rextester.com/GCIO55456

https://pastelink.net/y85a1oss

https://paste.artemix.org/-/4Rj4W-

https://pst.klgrth.io/paste/2za6j

https://wow.curseforge.com/paste/56da5c50

https://paste.toolforge.org/view/75742a57

https://www.wowace.com/paste/be362fd5

https://challonge.com/4h2ya0uh

https://pastelink.net/dsmq34ba

https://paste.rs/yfU

https://backlinktool.io/p/NGzeVJSY8eEzFuD3WfTl.html

https://pst.klgrth.io/paste/umjcw

https://controlc.com/9c54fcdb

https://www.pastery.net/kbgzru/

https://justpaste.it/7ugrb

https://sportsclud24.cookpad-blog.jp/articles/731947

https://www.zdronet.pl/main/fid/1/tid/47529/forum/thread.html

https://www.zdronet.pl/main/fid/1/tid/47530/forum/thread.html

https://techplanet.today/post/iuygifuydt-xfhd-f

http://smartsourcing.ru/blogs/personal/9855

https://cbstv.amebaownd.com/posts/35657006

https://www.bankier.pl/forum/temat_gf-hxfxd,55375757.html

https://www.bankier.pl/forum/temat_fg-ufdxxddh,55375771.html

https://www.onfeetnation.com/photo/albums/xfdh-xx-dsg

https://caribbeanfever.com/photo/albums/gc-fxxdg-xgg

https://paiza.io/projects/AFSHsRT_lTzhvm4UmqyLZA?language=php

Typical types of coatings that are evaluated include: paint coatings, anodized aluminium, zinc on steel and a variety of other plating/base metal combinations.

Due to its widespread usage, it is regarded as a “universal” test. One of the greatest advantages of this test is that it can be performed on multiple materials. Thus, salt spray testing is a well-defined test and often is an integral part of the metallurgical engineering process. With the changing times, new techniques and other new methods have begun to supplement the standard salt spray test, however, the ASTM B117 test is still considered to be the standard salt spray test. Thus, the salt spray test has made its own place in the science of metallurgy and applied engineering and will continue to be relied upon for many years to come.

Web Stories Trendy is a daily online news website covering and curating the latest trends in tech, health, travel, fashion, Guest posting services, entertainment and more. I write blogs and share knowledge to our all visitors you can find any article here or request to post article. Adminlinked .com is a web-based platform that offers businesses a complete suite of tools to manage their online presence.