Technology

Advantages and Disadvantages of Custom Cable Assembly

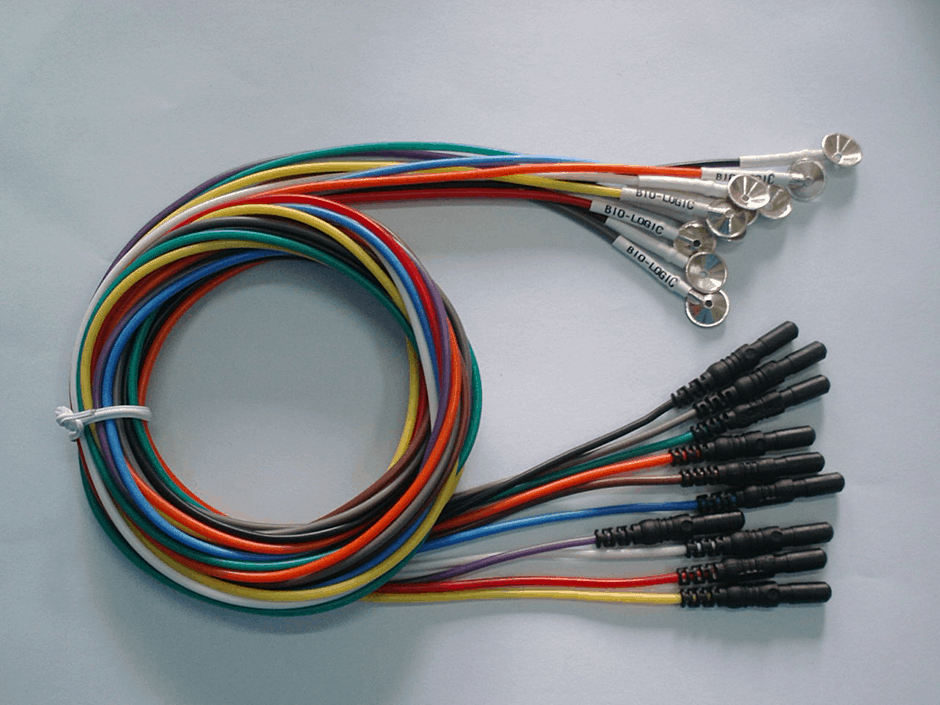

Custom cable assembly is bundled groups of cables that are cut to a specific length and then bound together. These cables are then covered in tape, sleeve, or cable tie. These types of cables are commonly used in mass production and the automobile industry, and can be designed to meet a specific application. The benefits of custom assemblies are many, but there are also many disadvantages to using them. Let’s examine some of these challenges.

First, custom cable assemblies are made to the exact specifications of the customer. As the name suggests, they are not standard. They can be made to any length and quality, and can also be installed in different ways, providing added functionality. Custom cable assemblies are not only easy to manage, but also take up less space than standard ones. Because of this, they can be made in almost any configuration. In addition, they can save on costs and space.

Custom cable assemblies can be made in many different lengths and configurations. The types of custom cable assemblies may vary, but the general guidelines are the same. There are many different types of assemblies, including miniature cables and push-pull control assemblies. There is no right or wrong size, so the only criteria that should be considered are the type of connectors, the wire, and the mounting location. Despite all of these factors, custom cable solutions are often made of heavy, durable materials that are safe to install in the intended application.

The main disadvantage of custom cable assemblies is their weight, but they are important for a variety of applications. They are not only lightweight and durable, but they are also highly flexible and able to accommodate a wide range of cables. In fact, they can even be built in a flexible manner, so they can be folded back for storage or transported. You can also find customized cables for electronic devices in the same way, which makes them an ideal choice for many applications.

Also Read: How to Find Available Domain Names

Another disadvantage of Custom cable assembly is the complexity. Depending on the type of assembly required, cables can be incredibly complex. Galaxy has the expertise and equipment to make custom cables for any application, including industrial applications. A company that specializes in custom cable solutions will be able to offer the most suitable cable for a given application. Its quality assurance department will ensure that the product is free from defects and meets or exceeds all specifications set forth by the customer.

Custom cable assemblies are perfect for applications that require long cable runs. They are designed to fit a specific installation and are compatible with a wide variety of different components. In addition, they are designed to withstand extreme temperatures, so they are ideal for outdoor applications. When designing custom cable assemblies, make sure to consider the environment and the installation area before ordering them. While standard cables are easy to manage, they can take up space and cause a mess in a building.